Activate your RAP

Convert RAP to like-new paving material with Activate

20 minutes to new, green asphalt

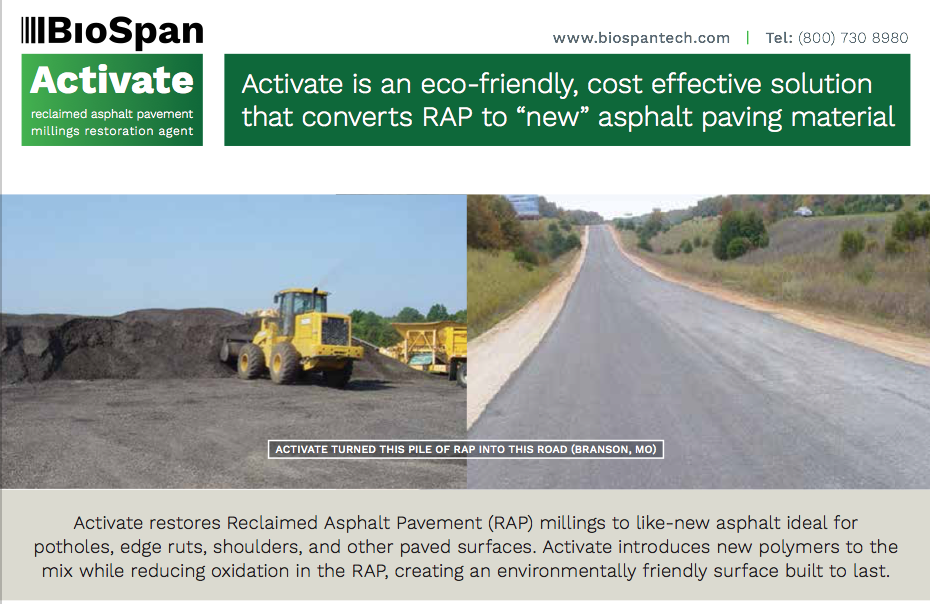

Activate is a 77 percent biobased solution that restores Reclaimed Asphalt Pavement (RAP) millings to like-new asphalt used for filling potholes, edge ruts, shoulders, and other paved surfaces.

With its patented chemistry, Activate introduces new polymers to the mix while reducing oxidation in the RAP. It has an ultra-low carbon footprint and does not require heating or additional oil. Mixing with conventional equipment takes only 20 minutes and the material cures in three hours with no tracking of raveling.

Activate is 77% biobased

Eco-friendly solution

Outperforms cold mixes and most hot mixes

No special equipment needed

Asphalt millings are considered hazardous materials that continue to pile up in outdoor storage. ACTIVATE is the answer for safely recycling Reclaimed Asphalt Pavement (RAP) into a new asphalt surface.

Mixing only 1/2 – 1 1/4 gallons of Activate per ton of screened millings, or RAP, creates a usable paving material that cures in three hours with no tracking or raveling. Activate uses patented chemistry to strengthen the mix by introducing new polymers and reducing the oxidized asphalt. Activate is the perfect solution for potholes, edge ruts, and shoulders.

Compared to hot or cold mixes, Activate saves customers between 40 and 600% of their budget. Not only is it 77% biobased, but it has an ultra-low carbon footprint that makes it such an eco-friendly solution.

Use it everywhere you pave

Since it is not petroleum-based, we eliminate the need for additional oil, cutback, or other polymers to most RAP, including asphalt cement.

Store and stir it: After Activate is mixed with RAP, it can be stored for 2 to 6 months. Larger piles, over 100 tons, of the mixture can be left uncovered while smaller piles can be covered with tarp. Stored mixtures stiffen over time, but a simple spray of Activate will soften the mix before use.

Activate is ideal for:

The savings pile up

ACTIVATE is easily mixed by hand or in a pugmill. The easy-to-use formula takes about 20 minutes to initiate the chemical process, but is effortlessly applied to create a lasting new surface.

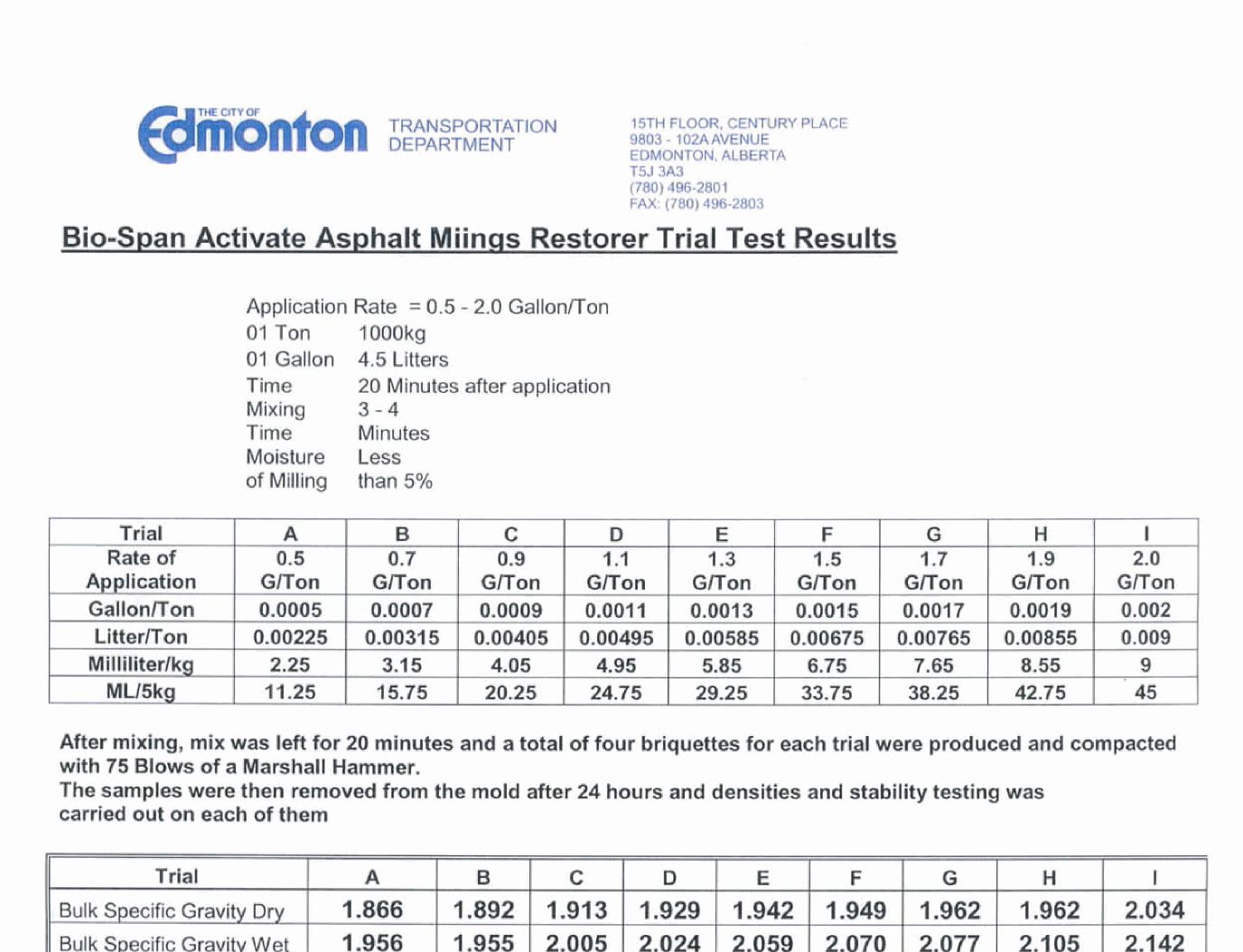

The results [of our blow testing] indicate that the mix at 0.5 Gmon of mix generally exceeds the requirements of the City of Edmonton Design and Construction Standards for Stability and Retained Stability for our cold mix patching materials. As a result a total of four trial patches have been installed by the City of Edmonton, Transportation Department.Hugh Donovan, P.Eng. Construction Services Engineer, Engineering Services, Transportation Department City of Edmonton

Resources

Get Activate

Interested in talking with a distributor or dealer? We'll put you in touch today.

Request a call- Related Pavement Solutions Products